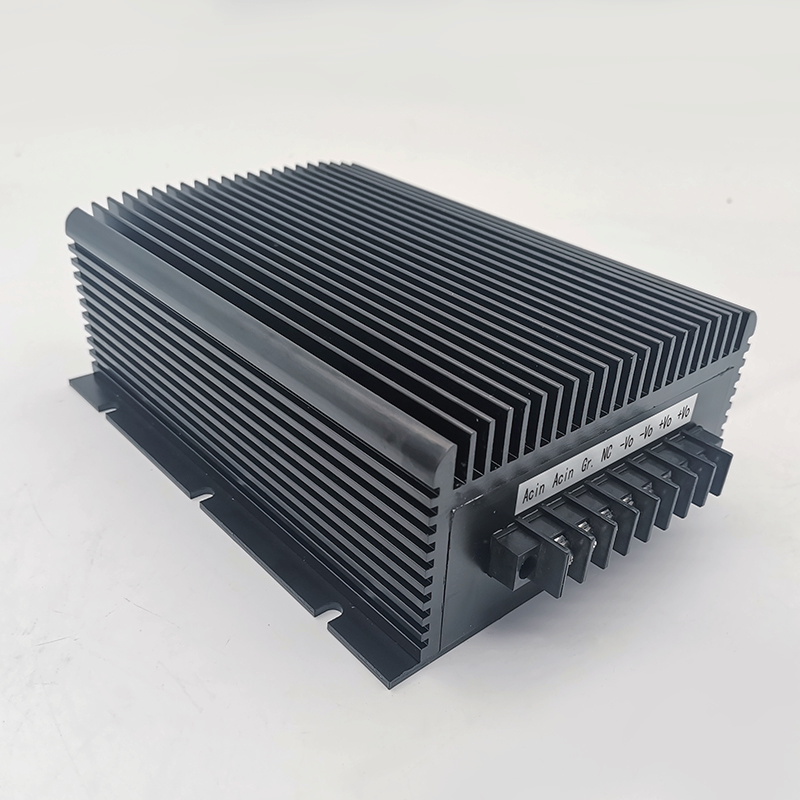

What does a vehicle power supply module look like?(2)

reasonable core structure and compact structure.

At the same time, in order to reduce the size of the module switching power supply, the switching frequency of the module switching power supply should be increased as much as possible. If it is to be increased to about 500kHz or higher, the loss of the ordinary magnetic core material is very large, and the magnetic core is easily overheated and magnetically saturated, and even It cannot work normally, so the high-frequency magnetic core material with excellent magnetic properties must be selected in the module switching power supply.

vehicle Marine boost/buck voltage power supply module The distinction between good circuit principles and bad circuit principles can often only be made from a professional perspective. At this stage, power modules can be roughly divided into two types: bare board and potting. The bare board can be based on intuitive methods, such as the layout of electronic components is reasonable, neat, generous, neat, and the solder joints are bright and straight. For encapsulated modules, it is not possible to see the internal conditions, but since the internal conditions are not exposed, it is much better in terms of safety and performance metrics. The soldering process can include hand soldering and wave soldering. The quality of the wave soldering process of mechanized production is better than that of manual soldering.

vehicle Marine boost/buck voltage power supply module Two: chip components

The core of the Marine boost/buck voltage power supply is the IC, just like the brain of the Marine boost/buck voltage power supply, the quality of the IC directly affects various parameters of the Marine boost/buck voltage power supply.