India acdc power module potting requirements(1)

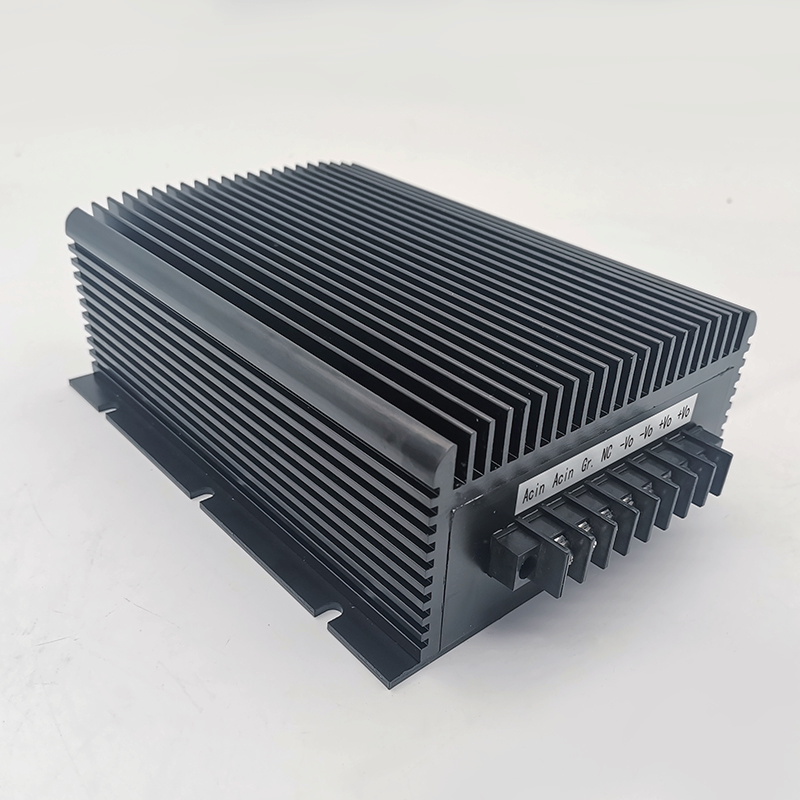

The potting of the acdc power module is very important. This process not only involves the protection of the power module potting acdc power module (waterproof, moisture-proof, dust-proof, anti-corrosion, etc.), but also involves the protection of the power module. thermal design.

At the same time, the design of the high-frequency switching transformer winding in the module switching power supply is also very important. The winding of the high-frequency switching transformer not only affects the copper loss, but also relates to the coupling between the high-frequency switching transformer windings, and also affects the iron loss of the high-frequency switching transformer. Influence, the design and manufacture of high-frequency switching transformers have a great impact on the performance of the module switching power supply

Commonly used power module potting materials are divided into three categories: epoxy resin, polyurethane and silicone rubber

Epoxies cannot be used for stress-sensitive and module sealing due to their hardness and are basically eliminated by module power supplies. However, due to its low cost, this epoxy is still used in cost-sensitive micropower supplies. Some domestic bad LED advertising screen power supply manufacturers also use this epoxy resin acdc LED advertising screen power supply module. However, due to stress problems, the failure rate of this LED advertising screen power supply is very high, and buyers are miserable.