What kind of 48V input power supply will be higher(1)

48V input power supply realizes voltage conversion. For example, when the mobile phone is out of power, it needs to be charged, but the 220v voltage cannot be directly used in the mobile phone, which will cause the mobile phone to burn. At this time, a conversion device is needed to convert the voltage that the mobile phone can use. This conversion device is the power module. This article will introduce you what kind of 48V input power supply to choose, which will be more secure?

48V input power supply One: circuit design principle and process

HVDC module power supply

High-power switching high-voltage DC power supplies are widely used in large-scale equipment such as electrostatic dust removal, water quality improvement, medical X-ray machines and CT machines. The voltage is as high as 50~159kV, the current reaches more than 0.5A, and the power can reach 100kW.

Since the 1970s, some Japanese companies have begun to use inverter technology to rectify the mains and invert it to an intermediate frequency of about 3kHz, and then boost it. In the 1980s, high-frequency switching power supply technology developed rapidly. Siemens of Germany uses power transistors as the main switching elements to increase the switching frequency of the power supply to above 20kHz. And the dry-type transformer technology is successfully applied to the high-frequency high-voltage power supply, the high-voltage transformer oil tank is cancelled, and the volume of the transformer system is further reduced.

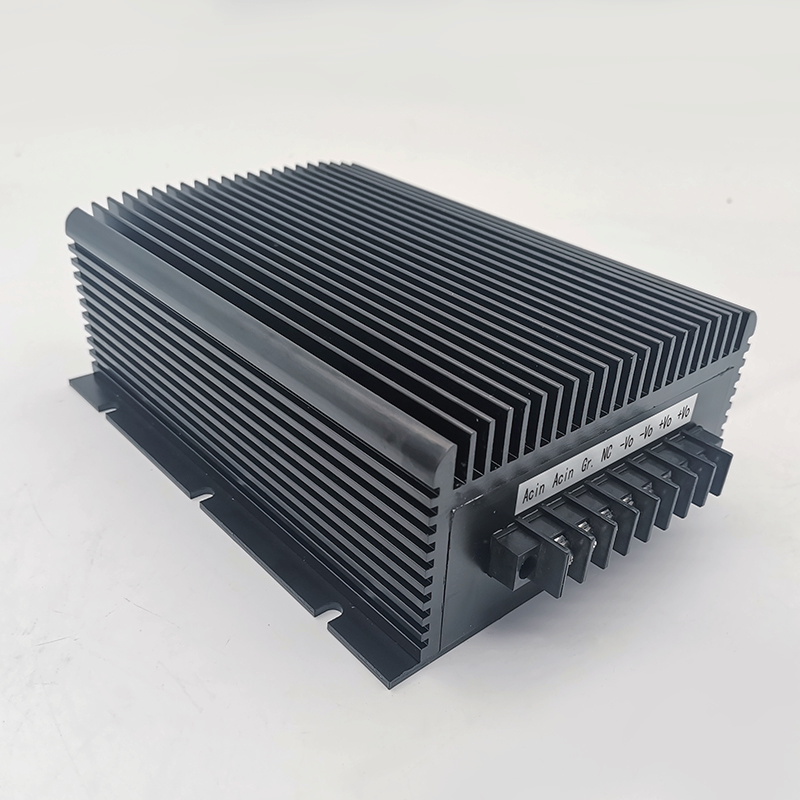

The quality of the resolution of the circuit schematic is usually done from a professional perspective. This power module can be divided into two kinds of bare board and packaged, according to an intuitive way of bare board, such as electronic components layout is reasonable and orderly, generous, orderly, and the net pad is lit upright. Also, stationary modules will not be able to see what's going on inside, but it's much better not to be exposed due to safety and performance levels. The soldering process can include both wave soldering and manual soldering, and the quality of the mechanized production process of wave soldering is superior to that of manual soldering.