Syria acdc power module potting requirements(1)

●High quality and reliable. Module power supply generally adopts fully automatic production, and is equipped with high-tech production technology, so the quality is stable and reliable.

Wide range of uses: The modular power supply can be widely used in various fields of social production and life such as aerospace, locomotives and ships, military weapons, power generation and distribution, post and telecommunications, metallurgy and mining, automatic control, household appliances, instrumentation and scientific research experiments. In particular, it plays an irreplaceable and important role in the field of high reliability and high technology.

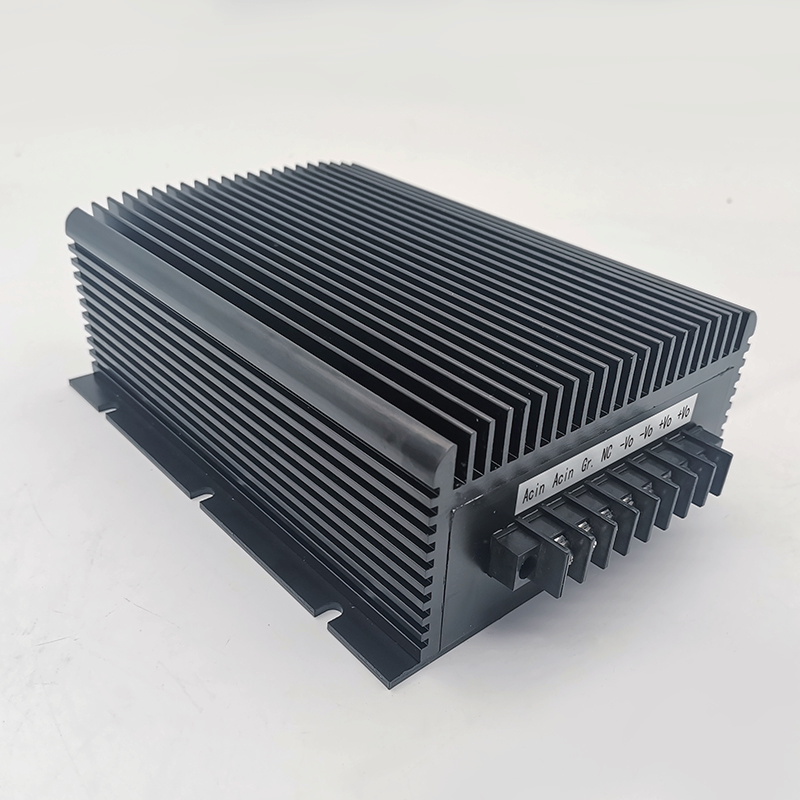

The potting of the acdc power module is very important. This process not only involves the protection of the power module potting acdc power module (waterproof, moisture-proof, dust-proof, anti-corrosion, etc.), but also involves the protection of the power module. thermal design.

Commonly used power module potting materials are divided into three categories: epoxy resin, polyurethane and silicone rubber

Epoxies cannot be used for stress-sensitive and module sealing due to their hardness and are basically eliminated by module power supplies. However, due to its low cost, this epoxy is still used in cost-sensitive micropower supplies. Some domestic bad Marine boost power supply manufacturers also use this epoxy resin acdc Marine boost power supply module. However, due to stress problems, the failure rate of this Marine boost power supply is very high, and buyers are miserable.