slovakia acdc power module potting requirements(2)

Epoxies cannot be used for stress-sensitive and module sealing due to their hardness and are basically eliminated by module power supplies. However, due to its low cost, this epoxy is still used in cost-sensitive micropower supplies. Some domestic bad LED advertising screen power supply manufacturers also use this epoxy resin acdc LED advertising screen power supply module. However, due to stress problems, the failure rate of this LED advertising screen power supply is very high, and buyers are miserable.

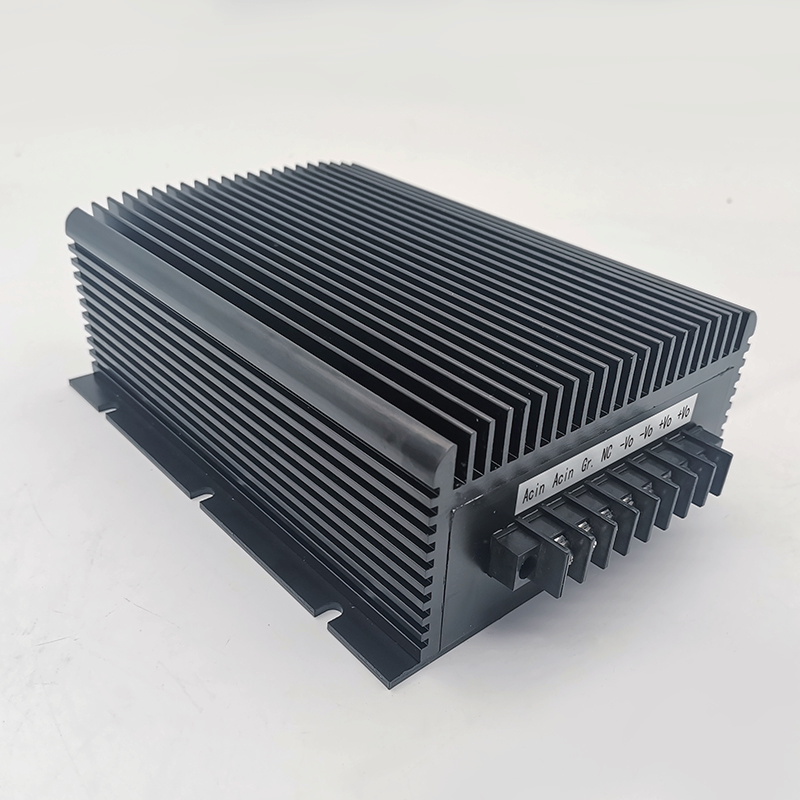

At present, the most commonly used power module is the addition of silicone. This kind of silica gel is generally 1:1, which is easy to operate. When acdc potting power modules, attention should be paid to its thermal conductivity. However, the bonding ability is not very strong, and it can be improved with primer.

In the early 1980s, the research on the distributed high frequency switching power supply system basically focused on the research of the converter parallel technology. In the mid-to-late 1980s, with the rapid development of high-frequency power conversion technology, various converter topologies appeared one after another. Combined with large-scale integrated circuit and power component technology, it became possible to integrate small and medium power devices, thereby rapidly Promote the development of distributed high-frequency switching power supply system research. Since the late 1980s, this direction has become a research hotspot in the international power electronics field.

Polyurethane has been used in China for a period of time, but due to its high hardness, inconvenient maintenance, and the price reduction of silicone rubber, the cost performance of polyurethane is not high.