China acdc power module potting requirements(1)

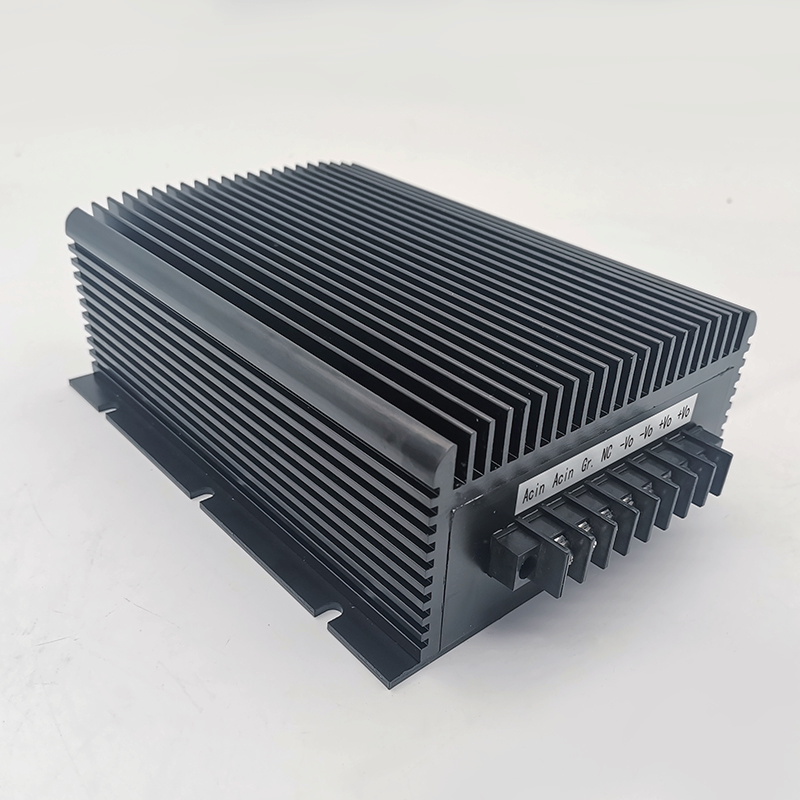

The potting of the acdc power module is very important. This process not only involves the protection of the power module potting acdc power module (waterproof, moisture-proof, dust-proof, anti-corrosion, etc.), but also involves the protection of the power module. thermal design.

Commonly used power module potting materials are divided into three categories: epoxy resin, polyurethane and silicone rubber

(2) Parallel connection of redundant hot backup. Connecting the output terminals of the same module through diodes in parallel can enhance the output capability and improve the reliability of the power supply system. In principle, if it cooperates with the corresponding output alarm circuit, put the module on the busbar that can be removed, so that the faulty module can be replaced in time. There is no limit to the number of modules connected in parallel in this way. D is generally a Schottky diode.

(3) Series expansion. Connecting the output terminals of the same module in series can double the output voltage and increase the power accordingly, and the series output terminals must be connected with diodes for protection.

Epoxies cannot be used for stress-sensitive and module sealing due to their hardness and are basically eliminated by module power supplies. However, due to its low cost, this epoxy is still used in cost-sensitive micropower supplies. Some domestic bad Marine boost/buck voltage power supply manufacturers also use this epoxy resin acdc Marine boost/buck voltage power supply module. However, due to stress problems, the failure rate of this Marine boost/buck voltage power supply is very high, and buyers are miserable.