Pakistan There are three elements in the procurement of DC module power supply(2)

Noise pollution has always been a major problem for manufacturers. In the early days, machinery and equipment would generate a lot of noise during work, which would affect the health of employees. According to the senior human resources department, it is very difficult to recruit workers at the moment. With the rise of Internet recruiting, it is easier for people to find jobs, but we are reluctant to work in production. If businesses cannot address noise pollution, they may not even find workers. After all, people these days take their health very seriously.

2. Insulation cannot be ignored.

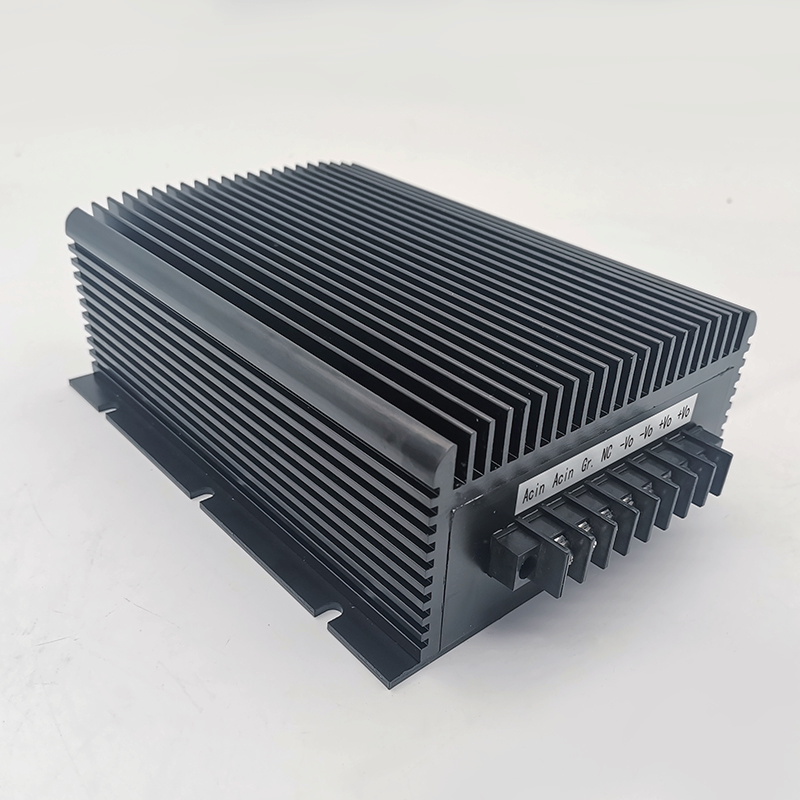

HVDC module power supply

High-power switching high-voltage DC power supplies are widely used in large-scale equipment such as electrostatic dust removal, water quality improvement, medical X-ray machines and CT machines. The voltage is as high as 50~159kV, the current reaches more than 0.5A, and the power can reach 100kW.

Since the 1970s, some Japanese companies have begun to use inverter technology to rectify the mains and invert it to an intermediate frequency of about 3kHz, and then boost it. In the 1980s, high-frequency switching power supply technology developed rapidly. Siemens of Germany uses power transistors as the main switching elements to increase the switching frequency of the power supply to above 20kHz. And the dry-type transformer technology is successfully applied to the high-frequency high-voltage power supply, the high-voltage transformer oil tank is cancelled, and the volume of the transformer system is further reduced.

The high-voltage power module will generate a very high voltage during operation. If someone touches it, the consequences are unimaginable. In order to ensure the safety of employees and avoid safety risks, it is necessary to understand the insulation when purchasing high-voltage power supplies. Only by ensuring that the insulation is good enough, can some unnecessary troubles be avoided.