What is the role of the control in the on-board DCDC?(3)

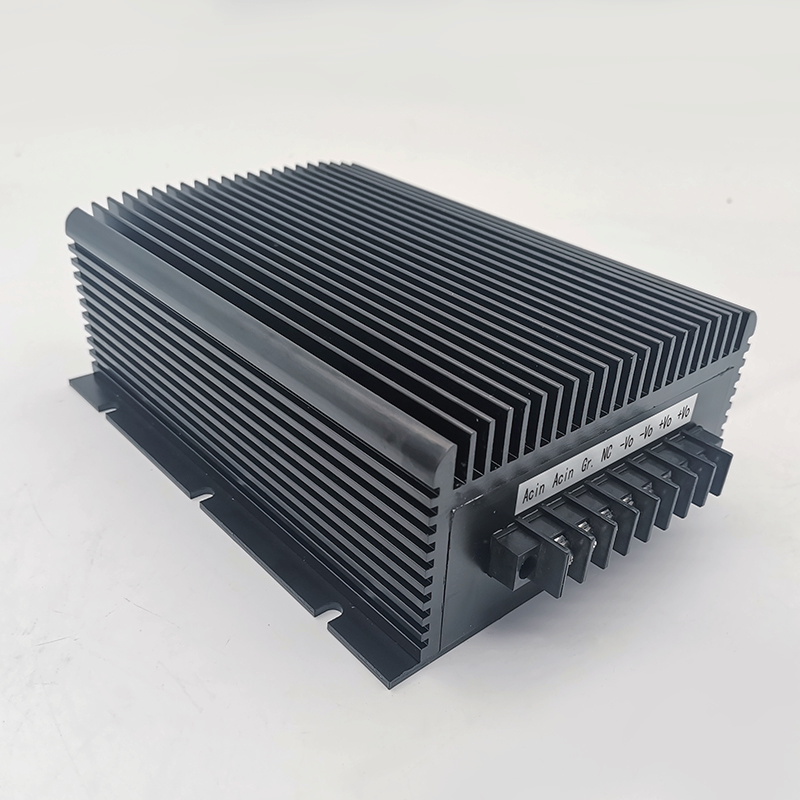

HVDC module power supply

High-power switching high-voltage DC power supplies are widely used in large-scale equipment such as electrostatic dust removal, water quality improvement, medical X-ray machines and CT machines. The voltage is as high as 50~159kV, the current reaches more than 0.5A, and the power can reach 100kW.

Since the 1970s, some Japanese companies have begun to use inverter technology to rectify the mains and invert it to an intermediate frequency of about 3kHz, and then boost it. In the 1980s, high-frequency switching power supply technology developed rapidly. Siemens of Germany uses power transistors as the main switching elements to increase the switching frequency of the power supply to above 20kHz. And the dry-type transformer technology is successfully applied to the high-frequency high-voltage power supply, the high-voltage transformer oil tank is cancelled, and the volume of the transformer system is further reduced.

Input protection circuit General DCDC module 48V input power supply supply products use built-in filters, which can meet the requirements of general 48V input power supply applications. If a more demanding power system is required, control in the on-board DCDC the input filter network should be added. Either LC or π can be used but care should be taken to choose a smaller inductance and larger capacitance.

In order to prevent the transient high voltage damage of the DCDC module 48V input power supply supply, it is recommended that the user connect the transient absorption diode to the input terminal, and cooperate with the fuse to ensure that the module is within the safe input voltage range. In order to reduce the common mode noise, Y (Cy) can be increased and several capacitors nf high frequency capacitors are generally selected. R is a fuse, D is a protection diode, and D is a transient absorption diode (P6KE series).